Bivingsville Manufacturing

Company - 1830 - 1876

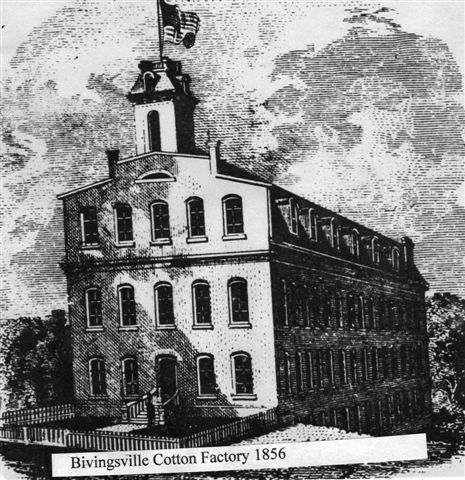

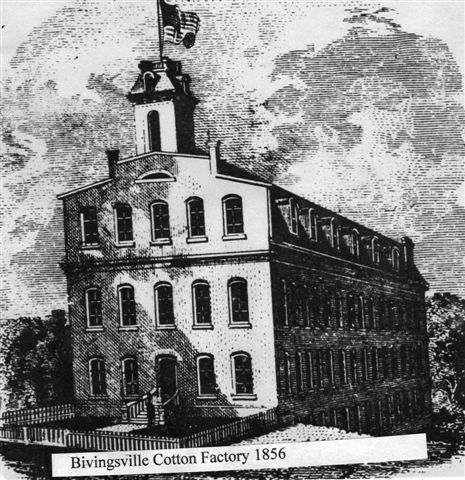

The forerunner of Glendale Mills, Bivingsville

Manufacturing Co. (Bivingsville Cotton Factory as it

was also called) was founded by Dr. James

Bivings who was born April 28,1787 in Edenton,

North Carolina. He was a Medical Doctor who had become

infatuated by the textile manufacturing process.

Bringing with him from Lincolnton N.C. craftsmen

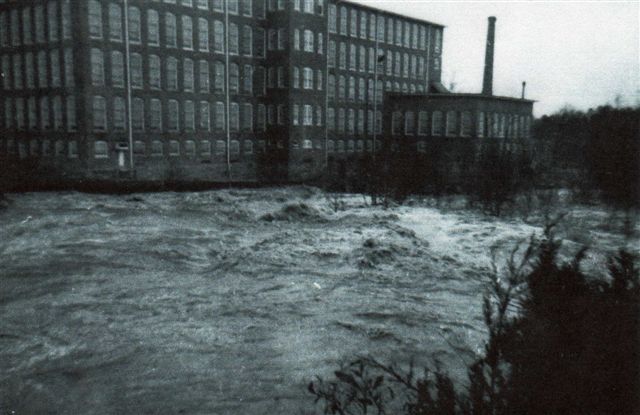

needed for the task, he bought land on the banks

of the Lawson Fork river in Spartanburg County in 1830

to build what was destined to become the oldest

continuous operating cotton mill in Spartanburg county

as of 1961. The factory with 1200 spindles and 24

looms was powered by a 26 foot water wheel with a 12

foot breast and started production about 1835. It was

reported that he had the machinery shipped from New

Jersey.

Old timers tell us that Dr. Bivings being a very

religious man, on one occasion stopped the mill asking

all employees to attend the revival which was being

held in the village. Along with the mill plant, Dr.

Bivings founded the village of Bivingsville which

consisted of some 12 homes, a community church in

which old timers said that school classes were taught

during week days, along with a shop or two. Mr.

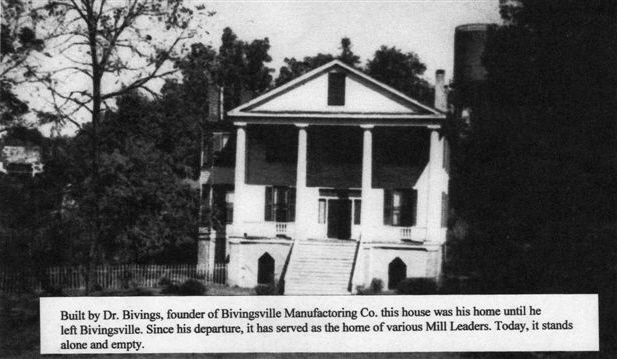

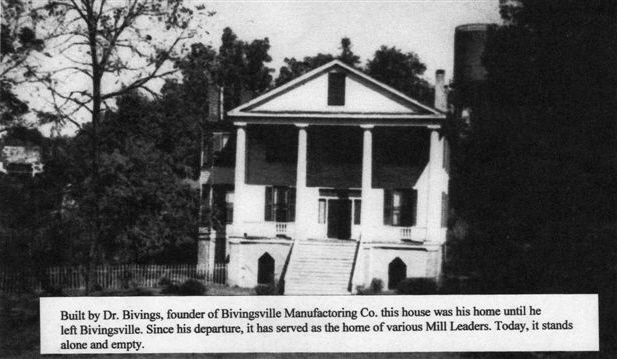

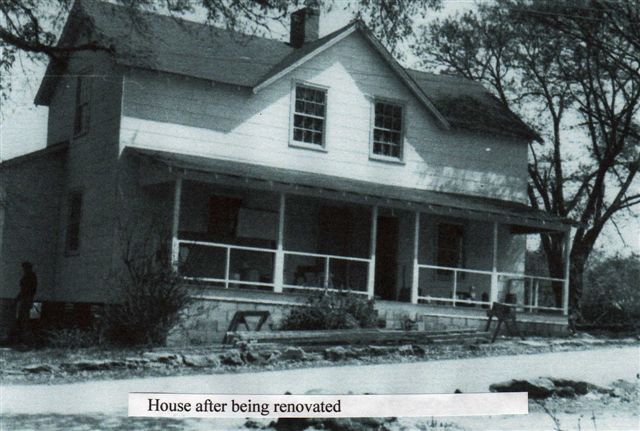

Bivings built two magnificent houses in Spartanburg

County which stand today. First he built (about

1834-35) a magnificent two and one half story house

located directly in front of the mill composed of

twelve rooms and a full size basement. A huge fire

place was located in every room.

Dr. Bivings built another two and one half story house

on North Church Street in Spartanburg in 1854 where he

lived for a while before selling to his brother

in-law, John Evins shortly after the civil war and

eventually became the home of John’s son, Choice

Evins, Dr. Bivings nephew, who later became President

of Glendale Mills.

Prospering for some 10-15 years the factory fell into

serious trouble in an economy crash at which time Dr.

Bivings divested himself of all interest in the

Bivingsville Mill. Dr. Bivings went on to build the

Crawfordsville Mill (later changed to Fairmont) which

was reported as being “very prosperous.” Dr.

Bivings died August 16, 1869 and was

buried in the Fairmont Methodist cemetery,

Fairmont, South Carolina not far from the mill he had

founded. Recent research has discovered the full text

of Dr. Bivings' obituary as published in several

publications in 1869. You can read this at Dr. Bivings Obituary.

After Dr. Bivings - 1854 -1876

Having left control of the

Bivingsville mill to Silas C. Leitner who had

been his partner, with the economy worsening and

finding himself in a hopeless situation by ever

increasing debts, Mr. Leitner left town in early 1855,

leaving the mill in bankruptcy to be sold in a

Sheriff's sale.

Forming an association among

themselves with a capital of some $30,000.00, J.

Bomar, Simpson Bobo, S.N. Evins, Vardry McBee,

J.C. Zimmerman and Dexter Converse bought the plant

for $19,500 in 1856 and operated for a number of years

under the name J.Bomar & Company with Dexter

Converse serving as Manager. A copy of this

association along with a picture of the Bivingsville

Mill was hanging in the mill office at Glendale the

last time I remember seeing it. When the Civil War

broke out, some being suspicious of a Yankee being in

town, Mr. Converse and Mr. Twichell, his brother

in-law who had come from N.Y. in 1859 to be bookkeeper

in the Bivingsville mill, volunteered for the

Confederate army but was released in about six months

being given an honorable discharge by Gen. Robert E.

Lee to return to the mill which was producing material

for the Confederate army. Along with war necessities,

swords, bowie knives and uniform material, the mill

was also producing shoes with wooden soles.

Following Mr. Bomar’s death,

(1868) Dexter Converse was promoted to President.

Having reorganized by 1875, the mill had some 5,000

spindles, 120 looms, 175 employees, a grist mill, saw

mill, cotton gin, machine shop and it is believed that

a community building and a mill store had been added.

The village had become the show place of the county.

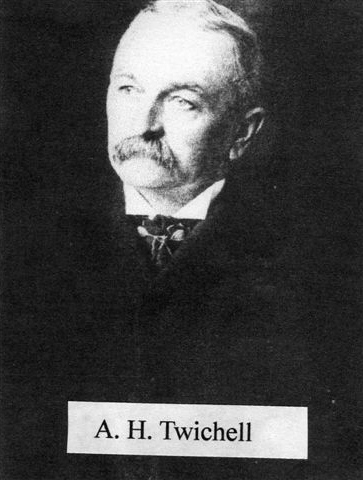

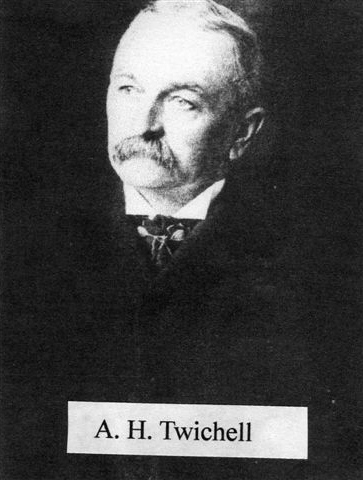

In 1876 Dexter Converse, A.H. Twichell and J.C.

Zimmerman bought all interest of the others, changing

the name to “The D.E. Converse Company”.The

name of the village was changed to Glendale at the

suggestion of Mrs. Converse and the Post-office name

was changed in 1878.

The D.E.Converse Company

1876-1946

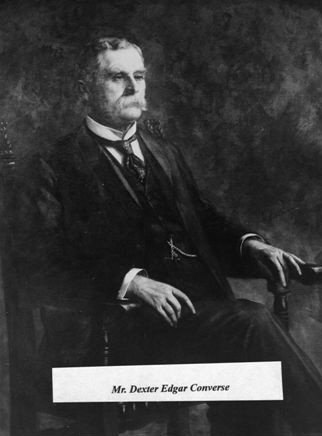

Dexter E. Converse, born in 1828

in Vermont worked in the cotton mills of Canada before

moving to Lincolnton, N.C. from whence he came to

Bivingsville, S.C. to become Superintendent of the

Bivingsville Cotton Factory in 1855. He married his 17

year old first cousin, Helen Twichell from New York in

1855. Having partnered with A.H. Twichell, his brother

in-law, and J.C. Zimmerman to buy the interest of all

others in the mill, they incorporated the Company

as,“The D.E. Converse Company” in 1889 naming Mr.

Converse President.

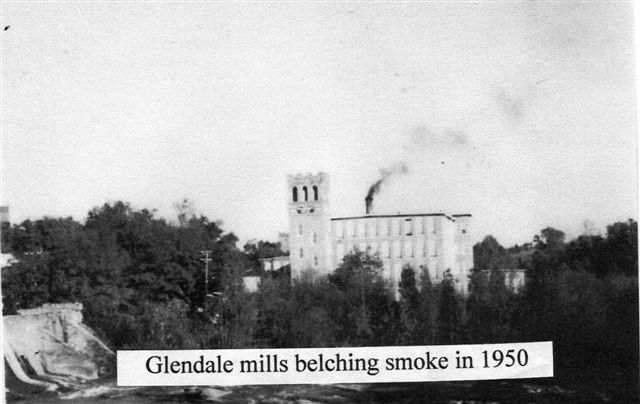

Under the leadership of Mr.

Converse, the mill continued to grow and prosper. In

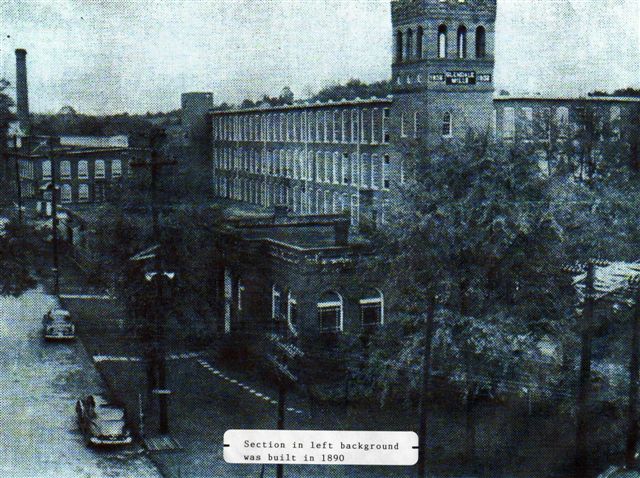

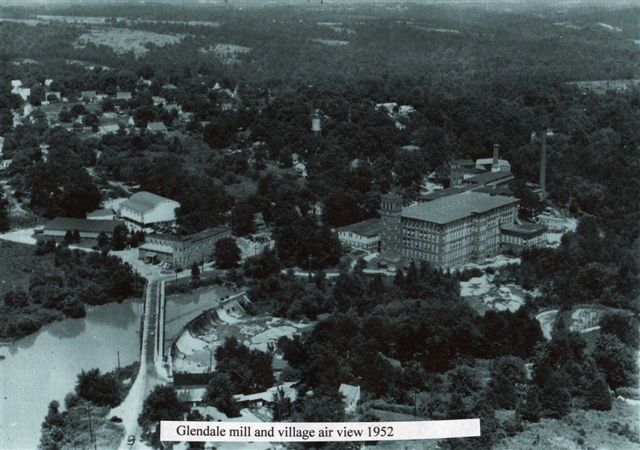

1890 the company had added a three story building to

the complex adding some 12,000 spindles. The village

had some 75 houses. Being a real genius in

textile management and finances, Mr. Converse

with his partners,built and founded Clifton No. 1 Mill

in 1880. In 1888 they built and founded Clifton

No.2 and in 1896, just three years before his death,

they built and founded Converse Mill. A news release

showed he was a stockholder in the Pacolet, Whitney

and Spartan Mills.

Before his death, Mr. Converse

and some of his business partners having a desire for

an institution in which their daughters could be

schooled, founded the college for girls which was to

be known as Converse College.(1889) The

auditorium was named “the Twichell Auditorium” in

honor of his wife’s (Helen Twichell) family name. Mr.

Converse served as President of the Board of Directors

for some ten years and it is said that he made up

school budget deficits out of his own pocket for the

first few years. Shortly before his death he had built

a home on Pine street in Spartanburg where he died on

Oct. 4, 1899, a “modest and much loved man”.

Mr. Twichell had built across

the street at the right of the Bivings mansion in

Glendale, a beautiful, spacious home for him and his

family where they lived until they too, built and

moved into their new home on Pine street in

Spartanburg, S.C. in 1882. Mr. Converse’s death left

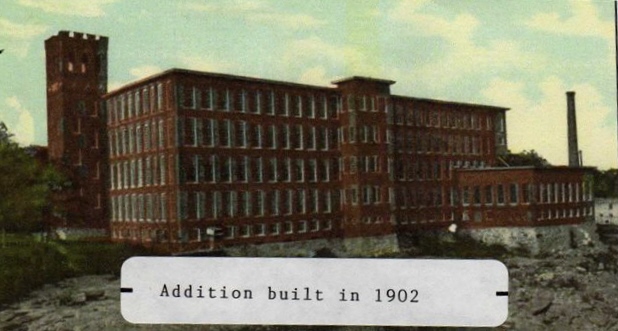

Mr. Twichell as President. Under the leadership of Mr.

Twichell a third building (five story) was built in

1902 having both water and steam power, adding 20,000

more spindles.

Mr. S. Jervey Dupre, who went to

work at D.E. Converse Co in 1879 as a sweeper and

became Company President and treasurer confirms these

figures in an interview which he gave at a later

date. Mr. W.E. Lindsey became president in 1916.

S. Jervey Dupre was secretary, R.F.(Fred) Bagwell had

become Superintendent in 1914 and served in that

capacity until 1944. Albert Brown was card room

supervisor, Will Rogers was boss spinner, Walter

Gregory was over the old mill weaving and Benard White

was over the new mill weave room. I. B.

Rhinehart supervised the cloth room and J. T. Varner,

(my Uncle) was Master Mechanic. In commenting about

the loyalty of the employees and their satisfaction

with their homes, Mr. Lindsey said; ”the people

love to live here, they seldom leave and when they do.

they are sure to come back”

A 1922 report showed the mill having 38,000 spindles. (I

suppose this included the 1200 in the original mill) It

had some 350 employees with a weekly payroll of

$4,000.00. There were 130 homes in the community which

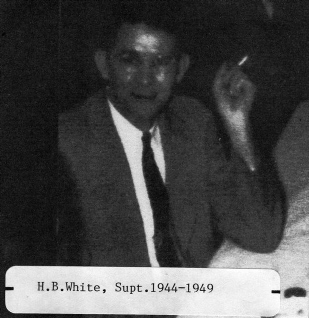

had both water and electricity. Benard White

became Superintendent in 1944 and continued until 1952.

Men who served as President of D.E. Converse Company

were: Dexter Edgar Converse, 1889-99; Albert H.

Twichell, 1899-1916, brother in-law to Mr. Converse;

W.E. Lindsey 1916-28; J.Choice Evins,1928-45, nephew to

Dr. Bivings founder of Bivingsville Cotton Mill;

S.Jervey Dupre, 1945-47.

Click on this link, Presidents,

to read more information about these men.

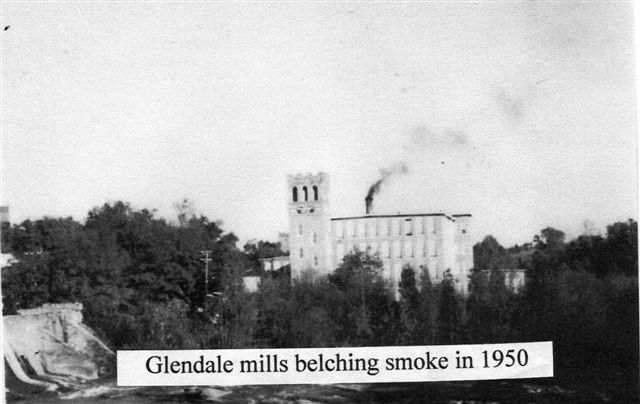

Glendale Mills 1946- 1961

The D.E. Converse Company was sold in 1946 to J. L.

Stifel and Sons, Warren Chaffin, President. The name was

changed to Glendale Mills in keeping with the village

name. Mr. Jervey DuPre Sr. who had bought his first car

from Sears Roebuck Co. in 1909, and had worked at the mill

since 1879, had been promoted to President and Treasurer

of the company and remained such until 1947 when he

retired from the company. Mr. Louis deLoach, from Springs

Cotton Mills, came to Glendale in 1947 as V.P. and General

Manager. Shortly after his arrival, Mr. deLoach announced

a million and half dollar improvement program destined to

change the mill, village and it’s people for life.

I was serving as Glendale Postmaster in 1948 when Mr.

deLoach approached me about joining the company as

Personnel Consultant/General Manager of the Mill Store and

it’s concessions. After considering the options before me

and experiencing his enthusiasm, I joined the company also

taking Supervision of the engineering and mechanical

department at a later date reporting directly to Mr.

deLoach.

Wishing to keep both written and photographic records of

the progress, he and I both took dozens of pictures along

with keeping records of the work being done. On February

26,1948 the Mill office was robbed of payroll money in the

amount of $18,000.00. Claude Manis was caught in

Tennessee and returned to Spartanburg to be charged and

convicted of the crime. After five years of hard work, the

program was basically finished. An Allison fence was now

enclosing the plant. (1947-48) A two story 20,000

square foot carding and spinning addition had been built

adding 8,000 spindles,4,500 twisters, 23 cards and 27

combers.

The plant had been renovated from bottom to top, the

interior having been painted throughout. Every piece of

cloth producing machinery had been moved, centralized to

individual departments. A new automatic high speed

elevator had been installed between mill 2 & 3.

Fluorescent lights were added, looms had been motorized. A

new electric control room had been built and new

switchboards had been installed in order to receive and

handle the additional power from Duke Power Co. needed for

the mill and the remodeled houses.

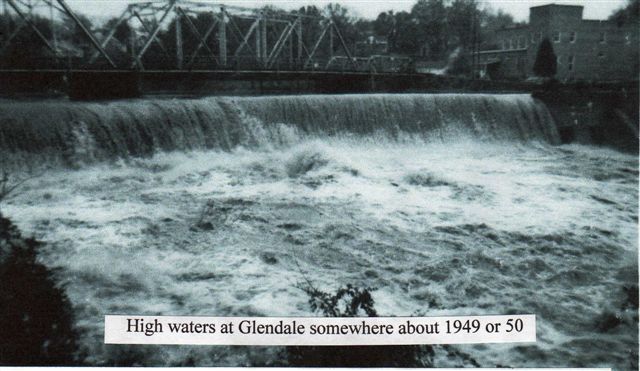

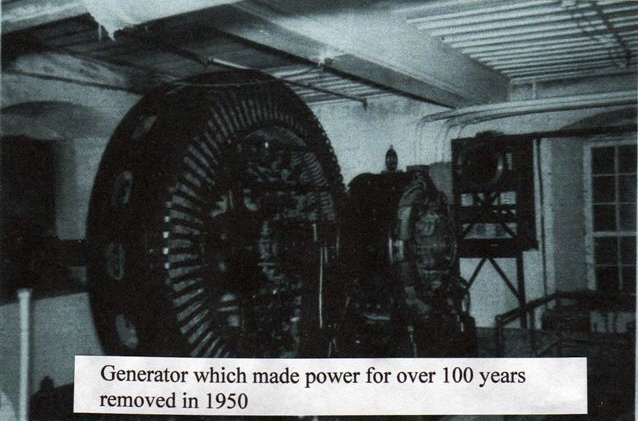

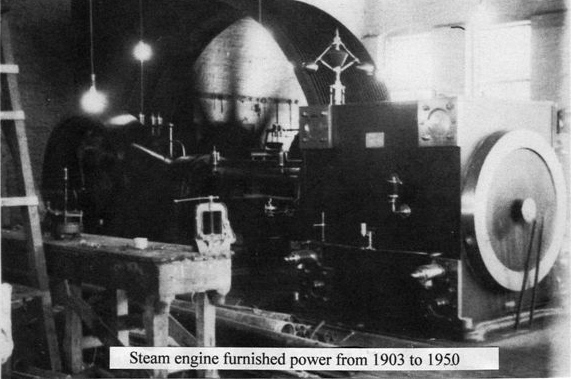

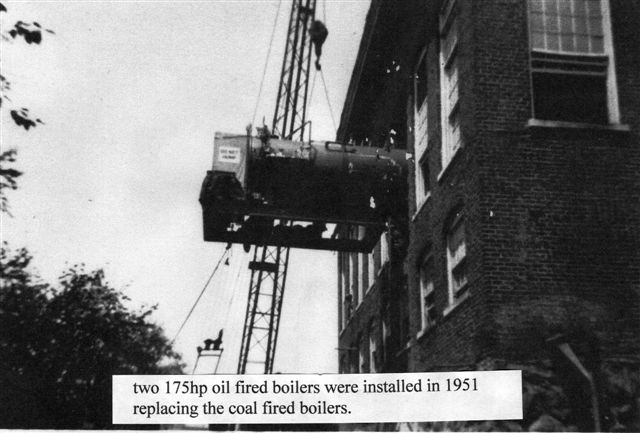

The water wheel, generator and steam engines which had

furnished power for the mill since 1903 and before, along

with the obsolete belt drives, had been taken out with all

machines having been motorized.(1950). Oil fired boilers

were installed in 1951.Obsolete equipment had been

replaced with new modern equipment. Worn equipment had

been rebuilt or replaced. A new 180 spindle

automatic spooler and overhead cleaning system had

been added. A canteen serving hot and cold sandwiches,

etc, had been built and in operation. A new one floor

weave room for combed material was being built and added

to the end of the plant next to the office.

(1953-54). At this time the Glendale plant had some 45,000

spindles and 1019 looms with some 600 full time mill

employees and some 200 temporary workers for renovation

and construction work.

A bonus system based on one’s longevity with the mill had

been set up. Large Christmas bags containing apples,

oranges, nuts, candies, cookies, pop corn and fruit

cakes weighing a total of some 30 pounds were

distributed to every employee each Christmas. Fourth of

July celebrations were being observed with food,

fun and games each year. Glendale Mills had also

purchased and were operating Douglasville Mills,

Douglasville, Ga.

The

Glendale Mill Office Robbery

In 1948, Glendale

Mills was the victim of one of the largest robberies

ever to take place in the Upstate. Read the full

details at Mill Office Robbery.

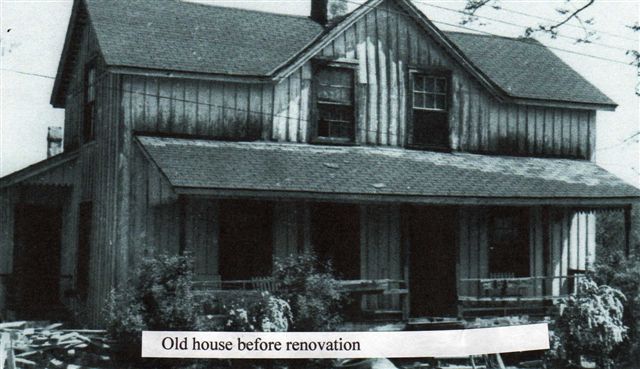

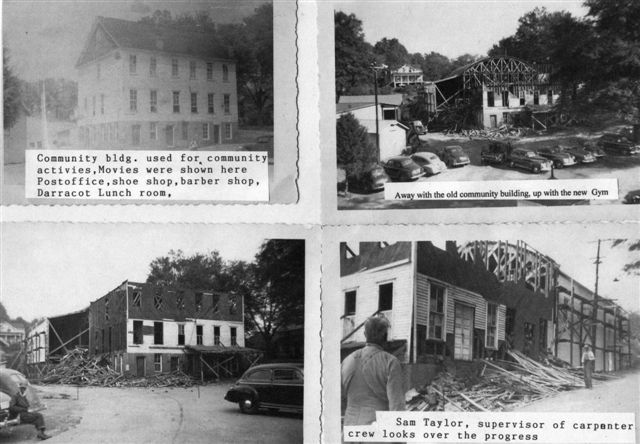

Glendale Mill Village Improvements

The little village which started

as Bivingsville in 1832 with twelve houses, a

community church and a shop or two had by 1946 become

a community of 158 houses with some 800

residents. A mill store had been added in the late

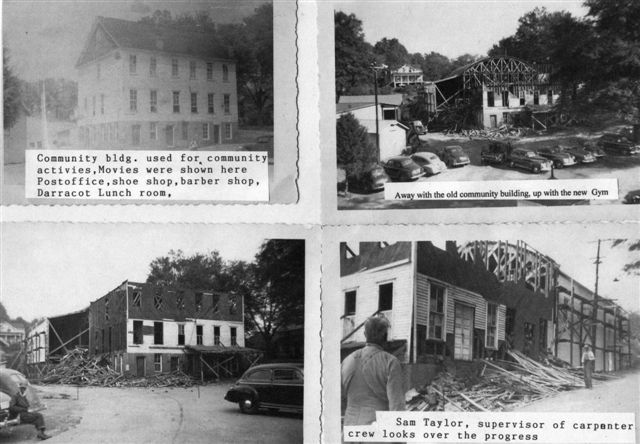

1800s along with a large community building in which

school classes were taught for a while and other

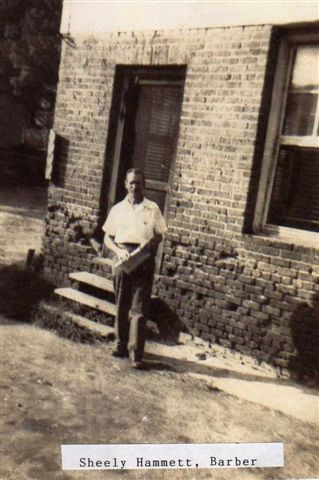

community activities were held. The post-office,

barber shop, shoe shop and a small lunch room were

also located in the building. Though the mill

store had been replaced in 1903 and in moderate shape,

and a modern brick school had been built and four

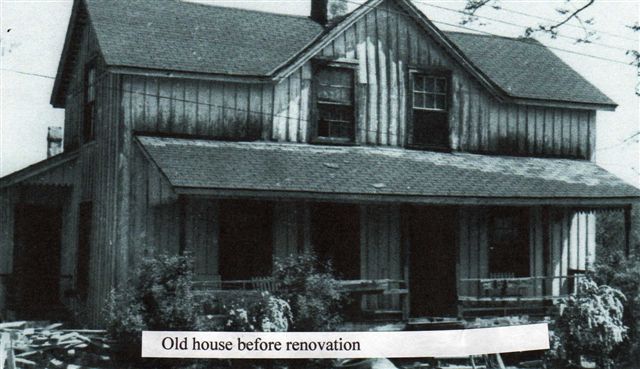

church buildings added, most all village houses

were in poor shape, badly in need of renovation. The

village houses had electricity and running water but

none had provision for hot water heaters or

stoves in that the houses had only 110 volts of

electricity which was insufficient for either. Most

all had bath rooms consisting of an old type commode

with the water tank mounted above the commode. Of the

158 houses, some had been moved with 40 having

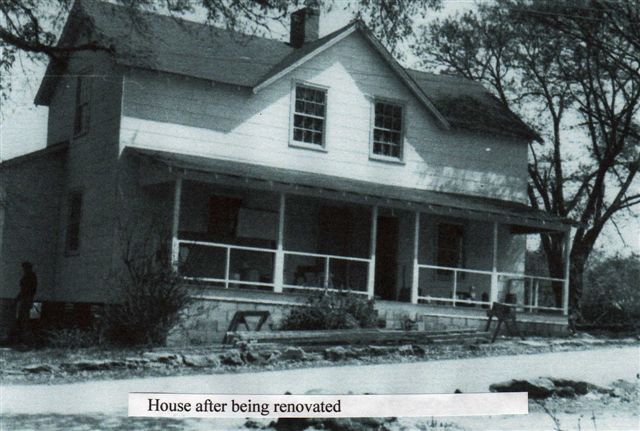

been torn down leaving some 118 to be repaired.

All had been renovated adding new modern

bathrooms with hot water heaters with 220 volt

electric service. Two clothes closets had been added

to most six room houses.

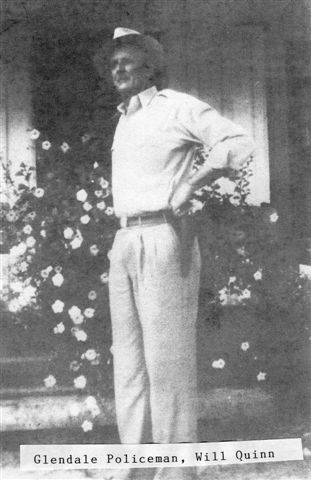

A new gymnasium had been built. The old community

building was torn down being replaced by a large gymnasium

in which the post-office, barber shop with hot and cold

showers, a shoe shop, cafe and magistrate office along

with a large recreation area were located in the basement.

Sports teams were being sponsored by the Mill company

along with a Boy Scout troop. The streets which were once

covered with cinders were now paved and renamed,

twisting among a village of some 118 houses, four

churches, three parsonages, 1 school, a large mill

store, gymnasium, three water tanks, a new post-office and

the first community cemetery.

Mr. deLoach had been promoted to Executive VP and

General Manager in October 1951 and to be sure, had made

his imprint on both the mill and the village. In 1955-56

the houses were sold with employees having first choice.

According to my records, when I joined the company they

owned 154 houses in the village, 4 in adjacent areas for a

total of 158 with some 70 being duplex having two families

per house for a total of some 8 to 900 residents. We had

torn down 40 leaving 118 homes to be sold. Of those

118 some 60 were 6 room duplex with perhaps 40 or more

having two family residents meaning that some 6 to 700

persons were living on the village at the time the houses

were to be sold. Of course the family with the longest

tenure with the mill had first choice of purchase.

To my knowledge, every family wishing to buy a home was

able to do so. While some paid cash, financial

arrangements had been made for employees to purchase

their home on installments if and when needed. The average

house sold in the price range of 3 to 5 thousand dollars.

(See receipt for typical

house.)

The Mill is Sold

The mill was sold through a merger with Indian Head

Mills in 1957 and Mr. deLoach announced his resignation,

effective immediately. He and his family were among the

finest families I have ever known and he was the best and

most considerate boss I ever worked with. He was strictly

professional. One of the first things he said in hiring me

was, Clarence, “we want to see that everyone is treated

fair”. While touring the plant together he would not allow

me to even buy him a coke from a machine or in the canteen

lest someone get the idea we were getting too close and

would not be objective in our individual opinions. He was

boss and called the shots and I always appreciated and

respected that fact. He was a genuine southern

Christian gentlemen. Local officials of Glendale Mills

were:

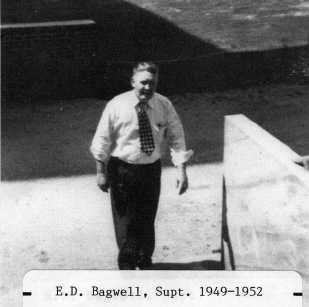

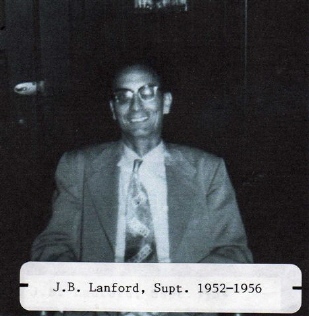

Mr. Louis deLoach, Exc. Vice President/General Manager;

H.B.White,Supt,1944-1949; E.D. Bagwell, Supt.1949-1951;

J.B. Lanford, Supt.1952-1956.

Shortly after Mr. deLoach‘s departure, with Indian Head

bringing in their own team, I was relieved of all

responsibilities in the mill and village but asked to stay

on as store and concessions Manager. The store was closed

in 1958 and I left the company. Following Mr. deLoach’s

death, his daughter gave me many, if not most, of his

pictures along with other material on Glendale. I have

used that along with data which I personally

had, in creating this story on the

history of Glendale Mills.

The above story and photos

about the mill's history were

furnished by Mr.

Clarence Crocker, a life long Glendale

resident, in May, 2009.

Personal Note about Crocker Family Connection

to the Textile Mill at Glendale

According to our family records, my great

grandfather worked in BivingsvilleCotton Mills shortly

after it started production in 1835 and was among the

first to live in the village. My grandfather who was

born at his home on Broadway street in Bivingsville

helped start the first drill loom in the plant and was

boss weaver for many years. My dad worked in the mill

most of his life and when I left, it was the first

time since the early days of it’s beginning (1835)

that a member of my family was not employed by

Glendale Mills or it’s precedents.

Footnote:

Many things have happened since 1958 which have

changed Glendale and it’s people. The mill stopped

production in 1961, shutting it’s doors. This left the

people of the community without employment. Some were

able to find work in plants nearby and were able to

keep their homes. Some sold their homes and moved

away. From the day it closed until the plant was

destroyed by fire (March 21, 2004) the property had

changed hands three or four times finally becoming

just a warehouse. Needless to say, this has had a

devastating effect on the people and the community.

Some houses are vacant, some have been torn down and

some are being poorly maintained . Though recent

interventions have begun to restore the community, the

fact is that the community of the fifties of kind,

hard working friends which we all loved and enjoyed,

to our dismay, no longer exists.

May 2009

Mill Ruins Today

Mill Ruins Today

(Photo courtesy of Jim Cody)